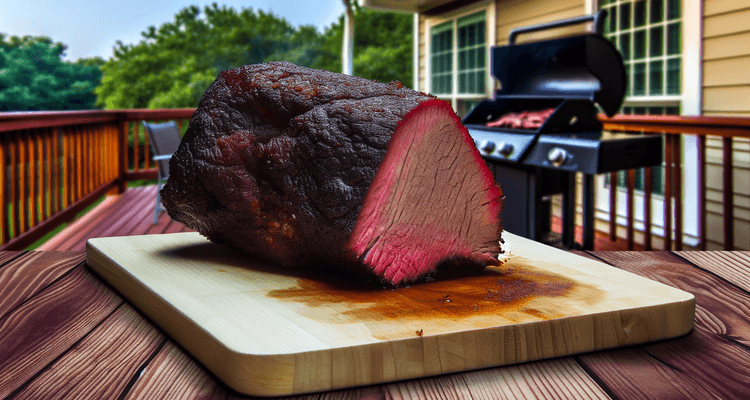

There’s something undeniably beautiful about slicing into a perfectly smoked brisket and revealing that signature pink band just below the bark. The smoke ring—that quarter-inch halo of rose-colored meat—has become the holy grail for backyard pitmasters and competition BBQ teams alike. But here’s the truth that might surprise you: while a smoke ring looks spectacular, it adds absolutely zero flavor to your meat. This guide will teach you the science behind smoke ring formation, the exact techniques to create a prominent ring, and why understanding this process will make you a better pitmaster—even if you choose not to chase the ring at all.

What is a Smoke Ring?

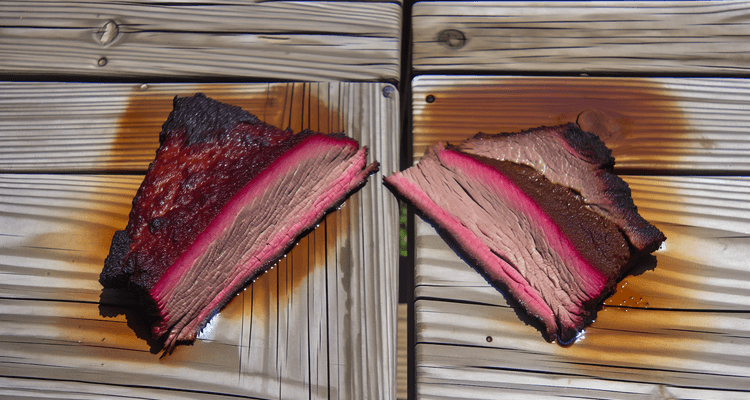

A smoke ring is that distinctive pink or red band, typically 1/8″ to 1/2″ thick, that appears just below the surface of smoked meat. It’s most prominent in beef and pork, particularly in cuts like brisket and pork shoulder, while less visible in poultry due to lower myoglobin content.

The smoke ring forms through a chemical reaction between gases from wood combustion and proteins in the meat—not from the visible smoke billowing from your smoker. This is a critical distinction that many beginners misunderstand. You can have heavy smoke without a ring, and you can have a perfect ring with minimal visible smoke.

The Flavor Myth

Let’s address the biggest misconception in BBQ right now: a smoke ring does not add flavor to your meat. Read that again. Despite what the Instagram photos suggest, this pink band is purely cosmetic. It’s a biological marker of how the meat cooked, nothing more.

Some of the best smoked brisket you’ll ever taste comes from restaurants that don’t chase smoke rings at all. The meat’s tenderness, juiciness, and actual smoke flavor come from proper temperature control, quality wood selection, and cooking time—not from that pretty pink line.

Cultural Significance in Competition BBQ

Interestingly, many BBQ competitions specifically instruct judges to ignore the smoke ring when scoring appearance. Why? Because it can be faked using curing salts containing sodium nitrite. A pitmaster can create a “perfect” smoke ring using Morton Tender Quick without ever lighting a fire. This is why serious judges focus on bark quality, moisture, tenderness, and flavor—the attributes that actually matter.

The Science Behind Smoke Ring Formation

Understanding the chemistry of smoke ring formation transforms you from someone following recipes to someone who understands BBQ at a fundamental level. Let’s break down exactly what’s happening inside that meat.

Understanding Myoglobin

Myoglobin is an oxygen-storing protein found in muscle tissue. It’s what makes raw meat appear red or pink—not blood, which was removed during slaughter. Think of myoglobin as tiny oxygen tanks embedded throughout the muscle fibers, ready to supply oxygen when the animal’s muscles need it.

Different meats contain vastly different amounts of myoglobin:

- Beef has the highest myoglobin content, especially in hard-working muscles like the brisket

- Pork has moderate levels, making it the second-best candidate for smoke rings

- Chicken has very low myoglobin, particularly in breast meat, resulting in minimal smoke ring potential

Fresh meat contains more myoglobin than aged meat. Younger animals have less than older animals. And muscles that worked hard during the animal’s life contain more than fatty, sedentary muscles. This is why a beef brisket—a hard-working chest muscle from a mature animal—showcases the most dramatic smoke rings.

The Chemical Reaction

When you burn wood or charcoal, the combustion process releases nitric oxide (NO) and carbon monoxide (CO) into the smoke. These gases do something remarkable when they encounter cold, moist meat: they dissolve into the surface moisture and penetrate into the outer layer of the meat.

Once inside, NO and CO encounter myoglobin molecules. Normally, myoglobin would bond with oxygen and then oxidize as the meat cooks, turning from red to brown. But NO binds to myoglobin approximately 100,000 times stronger than oxygen does. When NO bonds with myoglobin, it creates a new compound called nitrosomyoglobin—and this compound stays pink even when cooked.

Carbon monoxide works similarly, creating carboxymyoglobin, though the bond is only about 2 times stronger than oxygen (far weaker than NO’s bond). This is why nitric oxide is the primary driver of smoke ring formation.

Why the Smoke Ring Stops Growing

Here’s the critical limitation: myoglobin denatures (breaks down) when meat reaches approximately 140°F to 170°F internal temperature. Once denatured, the myoglobin turns brown permanently and can no longer form the pink nitrosomyoglobin compound.

This creates what I call the “window of opportunity”—the time between when your meat goes on the smoker and when it hits 140°F internally. Everything you do to create a smoke ring must happen within this window. After that, the ring is set, and no amount of additional smoke will make it deeper or more prominent.

| Temperature Range | Myoglobin State | NO/CO Activity | Smoke Ring Status |

|---|---|---|---|

| 32-140°F | Red/Pink (active) | High absorption | Actively forming |

| 140-170°F | Transitioning | Declining | Formation slowing |

| 170°F+ | Brown (denatured) | Minimal | Formation stopped |

Key Factors That Influence Smoke Ring Formation

Creating a prominent smoke ring isn’t about luck—it’s about understanding and controlling specific variables. Let’s examine each factor that affects whether you’ll get that Instagram-worthy pink band.

Fuel and Wood Selection

Not all fuels produce equal amounts of nitric oxide. The nitrogen content of your fuel determines how much NO will be available to create the smoke ring.

| Wood Type | NO Production | Smoke Ring Potential | Best Use |

|---|---|---|---|

| Hardwood (Oak, Hickory) | High | Excellent | Primary fuel or chunks |

| Charcoal Briquettes | Very High | Excellent | Base fuel + wood |

| Green Wood | High | Excellent | When available |

| Seasoned Hardwood | Medium-High | Very Good | Most common |

| Fruit Woods | Medium | Good | Flavor + moderate ring |

| Sawdust | Low | Poor | Smoke flavor only |

Here’s a surprising fact: charcoal briquettes actually produce more nitrogen compounds than wood because of their manufacturing process. If you’re serious about maximizing smoke ring depth, using charcoal as your base heat source with hardwood chunks added for smoke is more effective than burning pure wood. For a deeper dive into charcoal grilling techniques, check out our comprehensive guide.

Green (unseasoned) wood contains more nitrogen than seasoned wood because nitrogen compounds evaporate as wood dries. This is why some competition pitmasters seek out fresh-cut wood. However, green wood is harder to burn cleanly, so this is an advanced technique.

Sawdust creates plenty of visible smoke but doesn’t combust long enough to produce significant NO, which is why sawdust-based smoke systems produce weak smoke rings despite heavy smoke output.

Meat Selection and Preparation

The meat you choose determines your smoke ring ceiling. You simply cannot get a thick pink ring on chicken breast—the myoglobin content isn’t there.

| Meat Type | Myoglobin Level | Smoke Ring Potential | Notes |

|---|---|---|---|

| Beef Brisket | Very High | Excellent | Best showcase |

| Beef Ribs | Very High | Excellent | Ideal candidate |

| Pork Shoulder | High | Very Good | Prominent ring |

| Pork Ribs | High | Very Good | Reliable results |

| Pork Loin | Medium | Good | Thinner ring |

| Chicken | Low | Fair | Minimal ring |

| Turkey Breast | Very Low | Poor | Limited potential |

Fat cap thickness matters significantly. NO and CO cannot effectively penetrate thick layers of fat to reach the myoglobin in the underlying meat. If you want a pronounced smoke ring, trim your fat cap to 1/8″ or less. Brisket with a 1/4″ fat cap will develop a ring on the lean side but minimal ring under the fat cap.

Fresh meat contains more myoglobin than frozen and thawed meat, though the difference is subtle. What matters more is keeping the meat cold when it goes on the smoker, which we’ll discuss next. Understanding beef grades and quality can also help you select meat with optimal myoglobin content.

Temperature Control

Temperature control is where most smoke ring failures occur. The principle is simple: keep your meat below 140°F for as long as possible to maximize the window for NO absorption.

Start with cold meat. Don’t let your brisket come to room temperature before smoking—this is one time when the old BBQ advice is wrong. Meat straight from the refrigerator (around 35°F) stays in the smoke ring formation zone for an extra hour or more compared to room-temperature meat.

Maintain low smoker temperatures. The sweet spot is 225-250°F. Higher temperatures cook the meat faster, reducing the time available for smoke ring formation. Some competition teams start even lower—around 180-200°F—for the first hour.

Avoid hot and fast methods if smoke ring is your goal. While you can produce excellent BBQ with hot and fast cooking (275-300°F), the smoke ring will be thinner because the meat blows through the 140°F threshold too quickly.

Moisture Management

Nitric oxide and carbon monoxide must dissolve into surface moisture to penetrate the meat. A dry meat surface significantly reduces smoke ring formation.

Use a water pan in your smoker. The evaporating water creates humidity that condenses on the meat surface, keeping it moist and receptive to NO and CO. This is especially important in the first 2-3 hours.

Spritz periodically with water or a light liquid. Wait until after your bark begins to set (usually after 90 minutes), then lightly spritz every 45-60 minutes. Don’t spray too early or you’ll wash off your rub. Don’t use acidic liquids like vinegar—they can inhibit the chemical reaction.

Surface tackiness is ideal. That slightly sticky surface you get from the rub dissolving into surface moisture? That’s perfect for NO and CO absorption.

Timing: The Critical First Three Hours

If you take away one thing from this article, let it be this: the first three hours determine your smoke ring. After that, you’re just cooking meat.

During hours 1-3, your meat is climbing from refrigerator temperature (35°F) to around 140°F. This is when NO and CO can penetrate and bind with active myoglobin. The ring you see when you slice that brisket 14 hours later was formed entirely during those first three hours.

This is why some pitmasters worry obsessively about smoke management early in the cook but become more relaxed later. Once the meat hits 170°F internal, adding more wood won’t deepen the ring—it only adds flavor.

How to Create a Smoke Ring: Complete Step-by-Step Guide

Now that you understand the science, let’s put it into practice. This step-by-step guide gives you the best chance of creating a prominent smoke ring using proven techniques.

Before You Start: Preparation

1. Select your meat. Choose beef brisket or pork shoulder for the most dramatic results. These cuts have high myoglobin content and long cooking times that showcase the ring beautifully.

2. Trim the fat cap. Leave only 1/8″ of fat on the fat cap side. Be aggressive with trimming—the sacrifice in moisture protection is worth the gain in smoke ring penetration. On brisket, the lean side will naturally show a better ring than the fat cap side.

3. Keep meat cold. Store your trimmed meat in the refrigerator until the moment you’re ready to put it on the smoker. Don’t let it warm up on the counter. Some competition teams even partially freeze their brisket for maximum effect.

4. Apply rub lightly. Use a thinner coat of rub than you normally would. A thick crust of seasoning can impede NO and CO penetration. You want flavor, not a barrier.

Setting Up Your Smoker

1. Choose your fuel. For maximum NO production, use charcoal briquettes as your base heat source with hardwood chunks (oak, hickory, or mesquite) added for smoke. This combination beats pure wood or lump charcoal. Learn more about wood selection for smoking to optimize your results.

2. Add a water pan. Fill your water pan completely. This is non-negotiable if you want a good smoke ring. The moisture it creates helps NO and CO dissolve and penetrate the meat surface.

3. Target temperature: 225-250°F. Preheat your smoker to this range. Consistency matters more than the exact temperature, but staying below 250°F extends your smoke ring formation window.

4. Prepare wood chunks. Have 4-6 fist-sized hardwood chunks ready. You’ll add them throughout the first 3 hours to maintain steady smoke production.

The Smoking Process: Hour by Hour

| Hour | Meat Temp Range | Smoker Temp | Action Required | Smoke Ring Status |

|---|---|---|---|---|

| 1 | 32-60°F | 225-250°F | Add wood chunks, no spritz | Actively forming |

| 2 | 60-100°F | 225-250°F | Optional light spritz | Actively forming |

| 3 | 100-140°F | 225-250°F | Monitor bark, light spritz | Formation slowing |

| 4-6 | 140-170°F | 225-250°F | Maintain temp | Formation stopped |

| 7+ | 170-205°F | 225-250°F | Cook to doneness | Ring is set |

Hour 1: Place your cold meat directly on the grates. Add 2-3 hardwood chunks to your charcoal. Maintain 225°F smoker temperature. Don’t open the lid unless absolutely necessary—you want steady heat and smoke. Your meat temp will be climbing from 32°F to around 60°F. NO and CO absorption is at maximum during this hour.

Hour 2: Your bark is beginning to form but isn’t set yet. You can do a very light spritz with water if the surface looks dry, but it’s usually not necessary this early. Add 1-2 more wood chunks if your smoke has thinned out. Meat temp: 60-100°F. NO and CO absorption remains high.

Hour 3: Now your bark is setting up nicely. Give it a light spritz if the surface looks dry—just enough to add moisture without washing off the bark. The meat is approaching the critical 140°F threshold. Smoke ring formation is slowing down. This is your last chance to maximize penetration.

Hours 4-6: Smoke ring formation has stopped. The myoglobin has denatured and turned brown throughout most of the meat, except for that pink band you’ve created. Now you’re just focusing on cooking the meat to your target internal temperature. You can wrap in butcher paper during this phase without affecting the existing ring. Learn more about using butcher paper for BBQ to get the best results.

Hours 7+: For brisket, you’re in the home stretch, pushing toward 195-205°F internal temperature. The smoke ring was set hours ago. Focus on achieving probe-tender doneness and proper resting for maximum juiciness.

Smoking Methods for Smoke Ring Development

Different smoking setups produce different results. Here’s how various methods compare for smoke ring creation.

Traditional Wood Smoking

Burning split hardwood logs produces maximum NO and delivers the most authentic BBQ experience. Oak, hickory, and mesquite are traditional choices. The challenge is maintaining consistent temperature—wood fires require constant attention and skill.

Best for: Experienced pitmasters who understand fire management and value traditional methods.

Smoke ring potential: Excellent, assuming you can control temperature fluctuations.

Charcoal + Wood Chunks (Recommended)

This is the method I recommend for most home cooks. Charcoal briquettes provide stable, predictable heat while wood chunks contribute NO and flavor. You get the best of both worlds: temperature control and smoke ring formation.

For a beginner’s guide to smoking, this method offers the highest success rate.

Best for: Beginner to intermediate pitmasters seeking reliable results.

Smoke ring potential: Excellent. The briquettes’ high nitrogen content actually boosts NO production.

Water Pan Method

This isn’t a separate fuel method but rather a technique you add to any setup. Placing a water pan in your smoker increases humidity, which enhances NO and CO condensation on the meat surface.

Best for: Anyone seeking a deeper smoke ring, regardless of smoker type.

Smoke ring potential: Adds 20-30% to ring depth in my experience.

Cold Start Technique

Some advanced pitmasters start with partially frozen or very cold meat (below 32°F if partially frozen). This extends the time the meat spends below 140°F, potentially adding depth to the smoke ring.

Best for: Advanced users comfortable with longer cook times.

Smoke ring potential: Can add 1/16″ to 1/8″ of additional ring depth, but requires several extra hours of cooking.

| Method | Pros | Cons | Smoke Ring Potential | Skill Level |

|---|---|---|---|---|

| Pure Wood | Maximum NO, authentic | Hard to control temp | Excellent | Advanced |

| Charcoal + Wood | Easy control, reliable | Less traditional | Excellent | Beginner-Int |

| Pellet Smoker | Convenient, consistent | Lower NO production | Good | Beginner |

| Electric + Wood Chips | Easy to use | Minimal NO from element | Fair | Beginner |

| Gas + Wood Chips | Temperature control | Low NO from gas | Fair | Beginner |

Troubleshooting: Why Your Smoke Ring Isn’t Forming

Even with perfect technique, smoke rings can be elusive. Here’s how to diagnose and solve common problems.

| Problem | Likely Cause | Solution |

|---|---|---|

| No smoke ring at all | Electric smoker with no wood, or meat started too warm | Use wood chunks/chips, start with cold meat |

| Very thin smoke ring (< 1/8″) | Too hot too fast, thick fat cap | Lower smoker temp, trim fat to 1/8″ |

| Uneven smoke ring | Uneven heat distribution, inconsistent moisture | Rotate meat, ensure even spritzing |

| Ring disappeared after slicing | Only appeared to be weak ring, or lighting issue | Actually may still be there, check under good light |

| Pink throughout (not just ring) | Used curing salt (nitrites) | This is not a true smoke ring |

| Dry bark preventing ring | Rub too thick, no moisture | Apply thinner rub, use water pan |

| Ring stopped too early | Meat heated too quickly | Start with colder meat, lower smoker temp |

The Seven Most Common Mistakes

1. Starting with room-temperature meat. This cuts your smoke ring window by 60 minutes or more. Always start cold.

2. Thick fat cap blocking NO/CO. Fat doesn’t contain myoglobin and impedes gas penetration. Trim aggressively.

3. No wood or insufficient wood. Gas and electric elements produce minimal NO. You must use actual wood.

4. Smoking too hot (275°F+). Higher temperatures cook faster, reducing the time available for ring formation.

5. Dry meat surface (no water pan). NO and CO need surface moisture to dissolve and penetrate. Humidity matters.

6. Applying rub too thick. That thick bark might look cool, but it blocks gas penetration in the critical first hours.

7. Using electric smoker without wood. The heating element itself produces no NO or CO. Wood chips or chunks are mandatory. If you’re using an electric smoker, make sure to add wood chips or chunks to generate the necessary gases.

Expert Tips for Maximum Smoke Ring

Want to take your smoke ring game to the competition level? These advanced techniques can add that extra depth and visual impact.

Competition-Level Techniques

Start with partially frozen meat. Some championship teams freeze their brisket for 2-3 hours before smoking. The partially frozen surface stays below 140°F for an extra 1-2 hours, allowing deeper NO penetration. This requires extending your total cook time significantly.

Use charcoal briquettes for the nitrogen boost. Lump charcoal burns cleaner, but briquettes contain more nitrogen compounds due to their manufacturing process. For smoke rings, briquettes win.

Add celery seed to your rub. Ground celery seed contains natural nitrites that enhance the pink color. Add 1 teaspoon per batch of rub. It’s not “cheating” like using curing salts, but it’s a gray area in some competition circuits.

Maintain surface moisture religiously. Have a spray bottle ready from hour 1. Every time you open the smoker to add wood or check temperature, give the meat a light mist.

Control temperature precisely. A good dual-probe thermometer helps you track both smoker temperature and meat internal temperature. When you see the meat approaching 130°F, you know you have maybe 20-30 minutes left for ring formation.

Maximizing Ring Depth

The difference between a 1/8″ smoke ring and a 1/2″ smoke ring often comes down to these factors:

- Trim fat cap to bare minimum (even less than 1/8″ if you’re confident in moisture management)

- Cold meat (35°F) into low initial temp (200-225°F) for first 2 hours

- Heavy initial smoke (3-4 wood chunks in the first hour alone)

- Water pan filled throughout the entire cook

- Avoid wrapping until after 140°F internal (wrapping earlier cuts off NO/CO access)

What NOT to Do

Don’t use curing salts (Morton Tender Quick, Prague Powder #1) to fake a smoke ring. Yes, they work. Yes, they create a beautiful pink ring. But it’s not a true smoke ring—it’s a curing ring. Most BBQ enthusiasts consider this cheating, and competition judges often recognize the difference.

Don’t judge meat quality by smoke ring. I’ve said it throughout this article, but it bears repeating: a thick smoke ring does not equal better BBQ. Focus on tenderness, moisture, and flavor. If you nail those three and get a great smoke ring, consider it a bonus.

Don’t sacrifice flavor for appearance. Smoke ring formation requires specific techniques (like cold meat and low temps) that extend cooking time. If that doesn’t fit your schedule or style, don’t stress about it. Great BBQ doesn’t require a smoke ring.

Don’t obsess. The smoke ring has become overly fetishized in BBQ culture. Some of the world’s best pitmasters don’t chase it. Your guests will remember the flavor and texture far longer than they’ll remember whether there was a pink line beneath the bark.

Frequently Asked Questions

Does a smoke ring add flavor to the meat?

No. This is the most common misconception about smoke rings. The smoke ring is purely cosmetic—a chemical reaction that preserves the pink color of myoglobin. It adds zero flavor. You can have incredibly flavorful smoked meat with no smoke ring, and bland meat with a perfect ring. The smoke flavor you taste comes from compounds in the smoke that interact with the fat and surface of the meat, not from the pink nitrosomyoglobin band.

What exactly causes a smoke ring to form?

Nitric oxide (NO) and carbon monoxide (CO) from burning wood react with myoglobin in the meat, forming nitrosomyoglobin which stays pink even when cooked. This reaction only occurs before the meat reaches 140-170°F internal temperature. The NO binds about 100,000 times stronger to myoglobin than oxygen does, which is why the pink color persists through cooking while the rest of the meat turns brown.

Can you get a smoke ring with an electric smoker?

It’s difficult but not impossible. Electric heating elements produce no NO or CO, so you must use wood chips or chunks to generate these gases. The smoke ring will be minimal compared to charcoal or wood-fired smokers. To maximize your chances: add moisture with a water pan, use plenty of wood chips/chunks, start with very cold meat, and maintain low temperatures (225°F) for as long as possible.

Why doesn’t my meat have a smoke ring?

Common causes: (1) Started with warm meat instead of refrigerator-cold, (2) Smoked too hot/fast, pushing through the 140°F threshold quickly, (3) Thick fat cap blocking NO/CO penetration, (4) No wood used (gas or electric with no wood chips), (5) Electric smoker without wood chips, (6) Rub applied too thick, (7) Dry meat surface with no moisture for NO/CO to dissolve into.

Can you fake a smoke ring?

Yes, unfortunately. Curing agents like Morton Tender Quick or Prague Powder #1 contain sodium nitrite which creates a pink ring without smoke. This is why competition judges often ignore smoke rings—they can be chemically produced. Some pitmasters also add ground celery seed to rubs, which contains natural nitrites. While less egregious than curing salts, it’s a gray area in competitions.

What’s the best wood for creating smoke rings?

Hardwoods like oak, hickory, and mesquite produce the most nitric oxide. Charcoal briquettes actually produce even more nitrogen compounds than wood. Green (unseasoned) wood produces more NO than dried wood, though it’s harder to burn cleanly. Avoid sawdust—it creates smoke but combusts too quickly to produce significant NO. For maximum smoke ring: charcoal briquettes as base fuel + oak or hickory chunks for smoke. For more information on wood selection, check out our guide to choosing the best wood pellets.

At what temperature does the smoke ring stop forming?

Generally around 140°F for most meats, though some research suggests up to 170°F for beef. Once myoglobin denatures (turns brown permanently), it can’t form new nitrosomyoglobin. This is why the first 2-3 hours are critical—that’s when your meat is climbing from refrigerator temperature (35°F) to the denaturation threshold (140-170°F). Everything after that is just cooking to your target doneness.

Should I start with cold meat from the refrigerator?

Yes! Cold meat stays below 140°F longer, giving NO and CO more time to penetrate and react with myoglobin. Meat straight from the fridge (35°F) vs. room temperature meat (70°F) can mean an extra 45-60 minutes in the smoke ring formation zone. Some competition pitmasters even start with partially frozen meat for maximum smoke ring depth, though this requires significantly longer cooking times.

How thick should a smoke ring be?

Typically 1/8″ to 1/2″ thick. Thicker isn’t necessarily better—remember, it’s not a flavor indicator. A 1/4″ ring is considered good and visually impressive. Anything beyond 1/2″ is exceptional but doesn’t improve the meat’s quality. A thin 1/8″ ring on a tender, juicy, flavorful brisket beats a thick 1/2″ ring on dry, bland meat every single time.

Is a smoke ring important for competition BBQ?

Interestingly, many competitions instruct judges to ignore smoke rings because they can be faked with curing agents. However, a nice smoke ring can enhance visual appeal, which factors into appearance scores. The best competition strategy: focus on flavor, tenderness, and juiciness—those actually matter. If you get a good smoke ring as a byproduct of proper technique, great. But don’t sacrifice cooking fundamentals to chase a cosmetic feature.

Why does my smoke ring look uneven?

Uneven heat distribution, inconsistent fat trimming, or uneven moisture on the meat surface. Ensure your smoker has good airflow and consistent heat across the cooking surface. Rotate the meat 180 degrees at the 90-minute mark if your smoker has hot spots. Trim fat evenly across the entire surface. When spritzing, make sure you’re hitting all surfaces uniformly, not just the side facing you.

Can I still get a smoke ring if I wrap my meat in foil?

Yes, but only if the ring has already formed before wrapping. Once you wrap (typically around 150-160°F internal temperature), NO and CO can’t reach the meat anymore because the foil creates a barrier. The existing ring will remain intact—the pink nitrosomyoglobin is stable and won’t turn brown. But no new ring will form after wrapping. This is fine since the smoke ring is usually fully set by 140°F anyway.

Conclusion

The smoke ring represents one of BBQ’s most beautiful paradoxes: it’s simultaneously meaningless and deeply significant. Meaningless because it adds no flavor and doesn’t indicate quality. Significant because it demonstrates an understanding of meat chemistry, fire management, and patience—the core skills that separate great pitmasters from weekend grillers.

Key Takeaways

- Smoke ring equals visual appeal, not flavor. Never confuse aesthetics with quality.

- The science: NO and CO from wood combustion plus myoglobin in meat equals pink nitrosomyoglobin.

- Critical factors: Cold meat, low temperature, moisture, hardwood, and the first 3 hours.

- First 3 hours are make-or-break. After the meat hits 140-170°F, smoke ring formation stops.

- Don’t obsess. Great BBQ doesn’t require a smoke ring. Tenderness, juiciness, and flavor matter more.

The Bigger Picture

Now that you understand smoke ring formation, you’ve gained something more valuable than the ability to create a pink band: you understand the intersection of chemistry, temperature, and time that defines all great BBQ. This same knowledge applies to bark formation, fat rendering, collagen breakdown, and moisture retention.

Next Steps

Try the cold meat plus charcoal plus hardwood chunks method on your next brisket. Monitor temperatures carefully using a good dual-probe thermometer. Keep surface moist with a water pan and periodic spritzing. Practice the technique, and most importantly, focus on the fundamentals: maintaining consistent temperature, developing good bark, and cooking to proper doneness.

Remember: a smoke ring is a beautiful thing, but the best BBQ is tender, juicy, and flavorful. If you achieve those qualities with a perfect pink ring beneath the bark, consider it a bonus. Your taste buds will thank you more than your camera will.

Now get out there and put some meat on the fire. Whether you end up with a trophy-worthy smoke ring or none at all, focus on making it the best BBQ you’ve ever cooked. That’s what really matters.

Contents

- What is a Smoke Ring?

- The Science Behind Smoke Ring Formation

- Key Factors That Influence Smoke Ring Formation

- How to Create a Smoke Ring: Complete Step-by-Step Guide

- Smoking Methods for Smoke Ring Development

- Troubleshooting: Why Your Smoke Ring Isn’t Forming

- Expert Tips for Maximum Smoke Ring

- Frequently Asked Questions

- Conclusion